|

All content © Roften Galvanizing Limited 2019 |

To contact us call: 0151-355 5757 Email: sales @roften.com |

|

Hot Dip Galvanizers, Shotblasters, Industrial Painters, Access Covers & Frames |

|

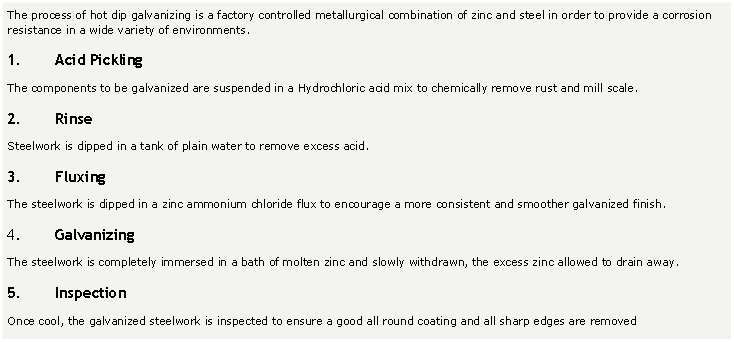

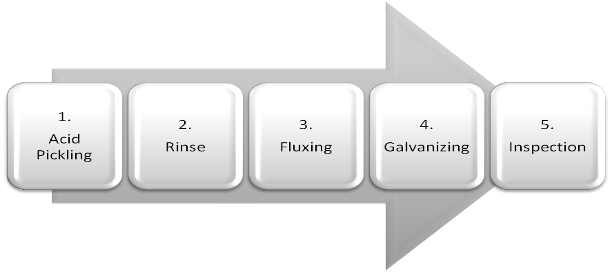

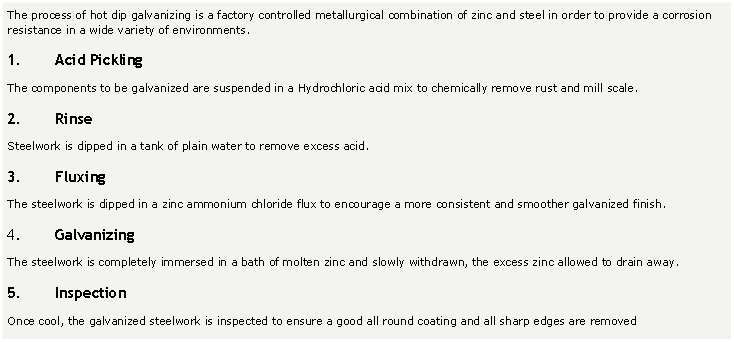

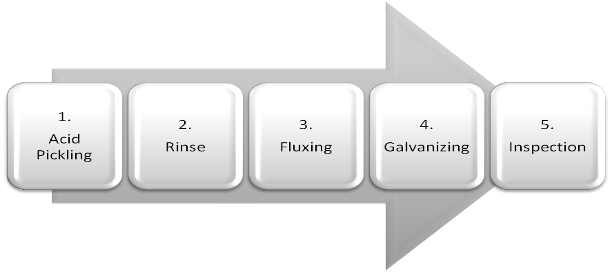

Galv Process |

|

All content © Roften Galvanizing Limited 2019 |

To contact us call: 0151-355 5757 Email: sales @roften.com |

|

Hot Dip Galvanizers, Shotblasters, Industrial Painters, Access Covers & Frames |

|

Galv Process |